Lightweighting critical to success in the EV era

Lowering the overall weight of vehicles is the key to success in the electric vehicle industry, said Srikumar S, Delivery Head of Technology Provider, Tata Elxsi.

Read Article

Third consecutive season with Defender Rally Series

Defender Rally Series and Tata Elxsi extend their partnership for the third consecutive season, facilitating the largest Defender Rally Series yet, featuring both UK and European Baja Championships.

Read Article

Good Designs Need a Human Touch

The importance of incorporating emotional elements into design to enhance user engagement and satisfaction.

Read ArticleDesigning the Cars of Tomorrow

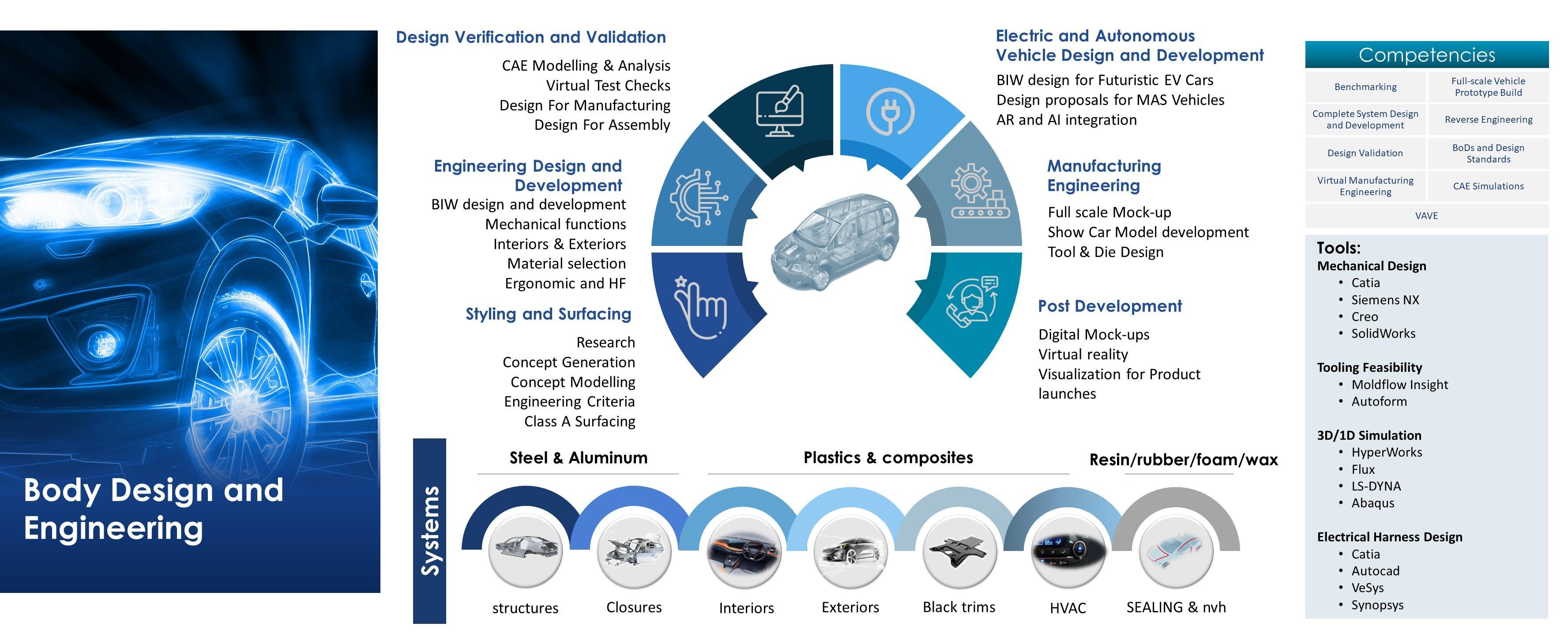

Tata Elxsi delivers comprehensive body design and engineering services, combining lightweighting strategies, modular chassis development, and advanced manufacturing. Our global network leverages deep expertise in material science, metallurgy, and simulation to help automotive OEMs develop next-generation vehicles. This data-driven approach enhances decision-making, ensures regulatory compliance, and drives efficiency, reducing costs and advancing long-term sustainability.

From styling and surfacing to verification and validation, we offer end-to-end solutions that streamline product development. With innovative design, VAVE (Value Analysis/Value Engineering), and sustainable materials deployment, our clients gain a competitive edge. We are committed to delivering future-ready vehicle architectures that accelerate time to market.

Here’s How We Can Help You

Integrated Body Design & Styling

- Create aerodynamic, eye-catching exteriors and interiors with advanced surfacing and collaborative digital workflows

- Incorporate human-centric design principles to enhance user comfort, safety, and aesthetic appeal

Modular design Expertise

- Expertise in developing Modular Chassis and Car bodies across segments for varied powertrain

Research and Design

- Lightweighting to meet regulations and maximize efficiency to address CASE requirements

- Dedicated VAVE teams to support at a system and commodity level

- Data-driven insights to help make more informed decision-making from multiple CAE simulations

Sustainable Manufacturing & Cost Optimization

- Integrate Value Analysis/Value Engineering for efficient resource use and cost reduction

- Implement novel material processes and automated manufacturing techniques to minimize waste, shorten cycle times, and enhance sustainability

Solution Framework

Our Body Design and Engineering services encompass comprehensive solutions from initial design verification to post-development. We specialize in CAD modeling, engineering design, styling, electric vehicle development, manufacturing engineering, and virtual mock-ups. Our expertise spans across materials like steel & aluminum to plastics & composites. We ensure innovative designs with robust validation processes for superior product development.

Design Verification and Validation

Our CAD modeling services include virtual test checks to ensure manufacturability before assembly begins. This process minimizes errors during production by validating designs through advanced simulation techniques.

Manufacturing Engineering

From BIW welding to show car coordination for events/expos, our manufacturing engineering services cover the entire spectrum of production needs ensuring seamless transition from design to final product with high precision.

Global Delivery Model

Access a worldwide network of engineering centers and specialized teams that offer round-the-clock design, simulation, and prototyping. Our distributed delivery model capitalizes on local market insights, ensuring region-specific requirements and regulations are met. This coordinated approach accelerates project timelines, improves resource allocation, and fosters consistent innovation across diverse automotive sectors.

Why Tata Elxsi?

- Pioneering body engineering solutions leveraging lightweight materials and advanced simulations for optimal performance and cost-efficiency.

- Global expertise in material science, metallurgy, and manufacturing techniques for robust and streamlined vehicle development.

- Proven VAVE strategies, optimizing parts and reducing costs without compromising critical safety or regulatory demands.

- Integrated approach to styling, engineering, and validation ensures accelerated time to market and reduced complexity.

- Holistic frameworks enabling seamless collaboration, data-driven decisions, and transformative cutting-edge innovation across diverse automotive portfolios.

In Focus

Information Hub

-

How does lightweighting benefit electric vehicles?

Lightweighting significantly influences EV range, performance, and cost. By reducing overall vehicle mass, manufacturers can enhance battery efficiency, lower energy consumption, and improve driving dynamics. Furthermore, using advanced materials—such as aluminum alloys, composites, or high-strength steels—also boosts structural integrity. As a result, EV platforms become more economical to produce, offering extended ranges and faster charging capabilities. This strategic approach ensures automakers meet increasing consumer expectations while adhering to evolving emissions and sustainability regulations. Ultimately, lightweighting supports EV adoption and fosters competitive advantages in a rapidly shifting automotive market.

-

What is VAVE and how does it optimize automotive projects?

Value Analysis/Value Engineering (VAVE) is a structured method focused on enhancing product functionality while reducing costs. By dissecting components, processes, and materials, VAVE identifies improvement areas without sacrificing performance or safety. This approach helps automotive OEMs manage resources more effectively, lower manufacturing expenses, and refine designs for greater appeal. Through VAVE, development teams systematically remove inefficiencies and prioritize value-added features that resonate with end-users. Consequently, automakers can balance innovation with affordability and bring highly competitive vehicles to market faster, ensuring better returns on investment.

-

How do CAE simulations accelerate vehicle development?

Computer-Aided Engineering (CAE) simulations enable engineers to model vehicle behavior under various conditions—structural stress, NVH, aerodynamics, or thermal loads—well before physical prototypes. By identifying potential flaws and optimization opportunities early, teams reduce rework, cut costs, and shorten development cycles. CAE also supports the exploration of multiple design configurations simultaneously, fostering innovative solutions that meet stringent safety and regulatory requirements. As a result, automakers gain robust data insights, hastening decision-making and driving more efficient, reliable body engineering processes. Ultimately, CAE technology empowers manufacturers to bring superior vehicles to market faster.

-

How can modular chassis approaches benefit both ICE and EV platforms?

Modular chassis designs standardize core elements—such as suspension, frame geometry, and load-bearing structures—while allowing customization for ICE, hybrid, or electric vehicles. This flexibility accelerates product development, since OEMs can reuse validated designs and components across multiple platforms. It also simplifies manufacturing, reduces inventory complexity, and streamlines supplier relationships. From a consumer perspective, modular systems enable faster model updates and technology integration, improving the overall vehicle experience. Whether targeting emerging EV demands or sustaining traditional markets, a modular chassis architecture fosters cost efficiencies, scalability, and competitive differentiation for automotive brands.

-

What emerging manufacturing techniques are shaping the future of automotive body engineering?

Additive manufacturing, composite molding, and hybrid joining methods are revolutionizing automotive body engineering. 3D printing allows rapid prototyping and low-volume production with minimal waste, enabling complex geometries that were previously infeasible. Composite materials, combining fibers and resins, provide superior strength-to-weight ratios. Meanwhile, hybrid joining—merging techniques like spot welding, adhesives, and mechanical fastening—enhances structural integrity. Together, these advancements drive cost-efficient, sustainable production, ensuring automotive OEMs can meet evolving performance, environmental, and consumer expectations in a highly competitive landscape.