Blog

Biological Equivalence: Streamlining Medical Device Testing with the Proposed ISO 10993-1 Revision

Introduction

The new draft revision of ISO 10993-1 integrates the risk management principles from ISO 14971 into the biological evaluation, emphasizing a systematic approach to ensuring the safety of medical devices. The risk management process from ISO 14971 ensures that potential risks are systematically identified, evaluated, and mitigated throughout the product lifecycle. This comprehensive approach focuses on leveraging existing data, reducing the need for animal testing and streamlining the regulatory process.

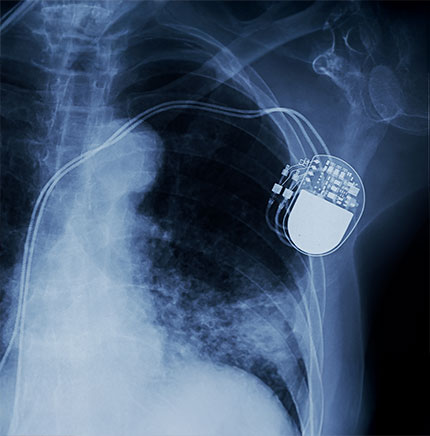

In this context, biological equivalence demonstration plays a critical role in the evaluation of medical devices. One of the most important aspects of biological equivalence is its potential to waive the need for animal testing. Traditionally, animal testing has been used to evaluate the biological safety of medical devices. However, with growing concerns about the ethics of animal testing and advancements in alternative methods, regulatory bodies are increasingly open to waiving animal testing if biological equivalence can be demonstrated.

What is Biological Equivalence?

A scenario where a new medical device or material is shown to be sufficiently similar in composition, physical characteristics, and manufacturing process to a comparator medical device for which there are existing data demonstrating biological safety in a relevant type and duration of body contact and no new or increased biological risks identified for the new medical device.

The ISO 10993-1:2024 draft outlines the stringent requirements for establishing this equivalence, making it a complex but essential part of the regulatory process.

A key aspect of the new draft is the Animal Welfare Considerations, which prescribes that physical and chemical characterization, as well as alternative in-vitro and in-silico techniques, must be applied first. Proving biological equivalence offers a viable way to waive off animal testing for new medical devices. By confirming that a new device is comparable to a pre-approved device, manufacturers can reduce the need for animal testing, in line with ethical concerns about animal welfare.

Challenges in Demonstrating Biological Equivalence

Proving biological equivalence is not straightforward. It requires high level of evidence and transparency in the documentation to show that the new device matches the approved device in terms of chemical composition, surface characteristics, and intended use. This process involves:

- Detailed Chemical Comparison: Ensuring that the chemical composition of the new device is identical to that of the approved device.

- Surface Characterization: Demonstrating that the surface properties, such as texture and porosity, are the same.

- Clinical Data: Providing clinical evidence that the new device performs similarly to the approved device in real-world use.

Benefits of Biological Equivalence

Despite the challenges, demonstrating biological equivalence offers significant benefits. It can:

- Reduce Testing: Leveraging predicate device data reduces or even eliminate the need for extensive biological safety testing, including animal studies.

- Accelerate Market Approval: Establishing equivalence can streamline the regulatory approval process, allowing new devices to reach the market faster.

- Ensure Patient Safety: Rigorous evaluation ensures that new devices are safe and effective for patients.

How to Demonstrate Biological Equivalence?

Example: A new device uses the same material with a change in elemental composition

A new implant is crafted from the same stainless steel alloy as a well-established and trusted implant. However, the new implant uses a slightly lower concentration of one element in the alloy. At first glance, this might seem like a minor change, but could it still be just as safe for patients?

This is where biological equivalence comes into play. By demonstrating that the new device’s biological performance is comparable to the existing device, even with changes in concentration, manufacturers can leverage existing data from the established device. It is important to underscore the risks associated with variations in material composition and biological safety throughout the device lifecycle, including clinical outcomes.

Conclusion

Growing concerns about animal welfare and the demand for faster device approvals are driving the need for biological equivalence, which provides a pathway to achieving both scientific and ethical goals. Essentially, biological equivalence simplifies and enhances the risk management process by reducing unnecessary testing, enabling manufacturers to focus on minimizing risks that are already well-understood from similar devices. It is a key aspect of the future of medical device evaluation.