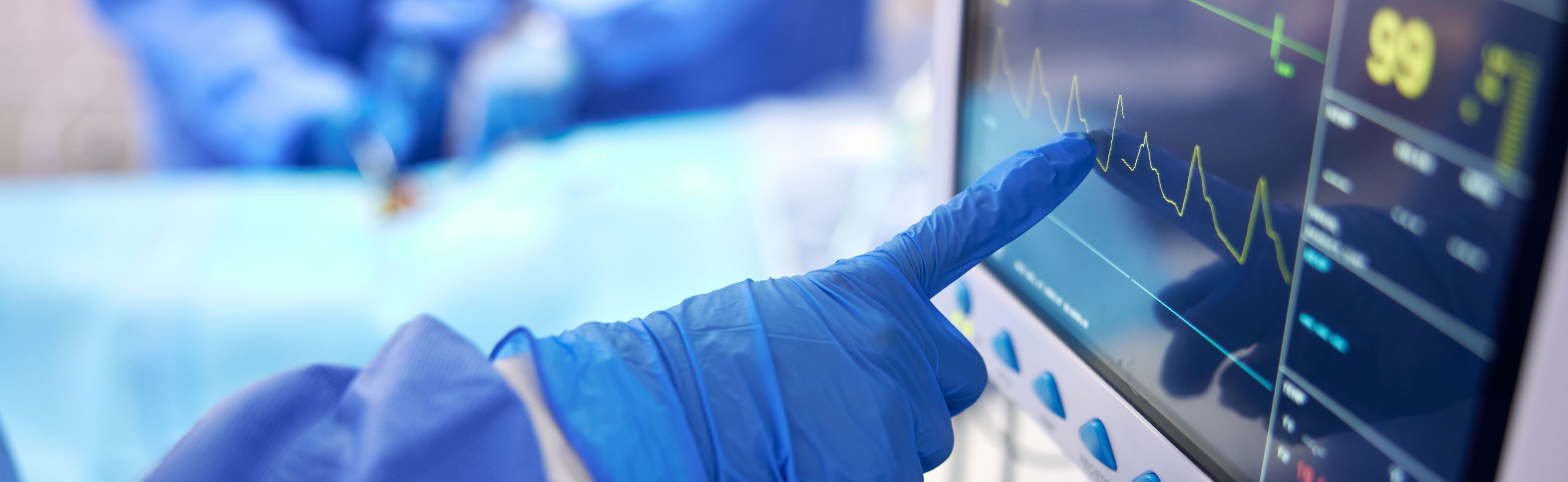

In the intricate and highly regulated world of healthcare, medical devices are the silent workhorses that empower clinicians and ensure patient safety. As these devices grow in complexity and integrate more sophisticated technology, ensuring their long-term reliability and effectiveness is more critical than ever. "Medical devices are crucial in healthcare and their reliability and longevity are vital for patient safety as well as the effectiveness of the treatment." This sentiment, shared by industry leaders, was the central theme of a recent webinar focused on a crucial practice: sustenance engineering.

This blog post delves into the key insights from a panel of experts from Philips Healthcare and GE Healthcare, exploring how a robust sustenance engineering strategy is essential for maximizing medical device lifespan, ensuring regulatory compliance, and navigating the challenges of a rapidly evolving industry.

What is Sustenance Engineering in the Medical Device Industry?

Sustenance engineering is far more than just routine maintenance. In the medical device context, it's a comprehensive discipline focused on the "upkeep of our systems that our customers are using for their day-to-day medical imaging and patient diagnostics," as Sentil Kumar, Site Leader & Senior Director, Molecular Imaging and CT, GE Healthcare puts it.

With product lifecycles often extending to 15 years or more, sustenance engineering ensures that devices remain safe, effective, and compliant throughout their operational life. This involves addressing a host of issues, from component obsolescence to evolving regulatory demands. As Niranjan Kumar, AVP - Distributed Energy Systems, Reliance Industries ((formerly GE Healthcare and Philips)) succinctly states, the goal of sustenance engineering is to prove that the device "is the same... neither better nor... inferior." This highlights the critical need for maintaining the validated state of the device, ensuring that any changes do not compromise its fundamental safety and efficacy.

Key Triggers and Challenges: A Marathon, Not a Sprint

The need for sustenance activities can be triggered by a variety of factors, including customer feedback, regulatory updates, supply chain disruptions, and new market demands. However, addressing these triggers is fraught with challenges.

Vinay Bari , Director R&D Operations, Ultrasound, Philips Healthcare aptly describes the process: "Unlike npi [new product introduction]... I look [at] sustain[ance] engineering... like a big marathon... it never ends." This marathon is characterized by several significant hurdles:

- Long Product Lifecycles vs. Short Component Availability: The long life of medical devices often outlasts the production of their electronic components, leading to significant component obsolescence issues.

- Evolving Regulatory Landscape: Constant changes in global regulations require continuous effort to ensure regulatory compliance, including re-certification and re-registration of products.

- Maintaining Reliability: Ensuring a device performs reliably year after year, despite component degradation, is a primary challenge impacting medical device reliability.

- The Ripple Effect of Small Changes: As Niranjan Kumar illustrated with a powerful example, even a minor change, like a single resistor in a bill of materials (BOM), can have massive consequences. A mistake that led to an incorrect component being used in 750 upgraded devices underscores the "criticality and kind of escalation" that can arise from seemingly insignificant modifications.

A Framework for Success: Prioritization and Execution

With a never-ending stream of potential issues, how do organizations effectively prioritize and execute sustenance activities? The experts highlighted a customer-centric and risk-based approach.

Vinay Bari shared his "Three Fs" framework for prioritization: Field, Factory, and Features.

- Field: The highest priority is given to issues reported from the field that directly affect customers and patient safety.

- Factory: Next are issues that impact the manufacturing and supply chain, threatening business continuity.

- Features: Finally, new features and enhancements are prioritized based on market and customer needs.

This approach, combined with robust risk management, structured Change Control Boards, and the adoption of agile methodologies, allows organizations to manage the complexities of medical device product lifecycle management effectively. Success is measured through a variety of Key Performance Indicators (KPIs), including device uptime, customer satisfaction, cost of non-quality, and overall medical device reliability.

The Future of Sustenance: AI, Digital Twins, and ESG

The future of medical device maintenance is being reshaped by powerful technological advancements and a growing focus on Environmental, Social, and Governance (ESG) factors.

- Technological Advancements: The panel envisioned a future where sustenance engineering becomes more predictive and proactive, driven by data and AI.

- Generative AI: Niranjan Kumar sees a "boom" in using generative AI for tasks like analyzing customer complaints and assessing the impact of changes, leading to greater efficiency.

- Digital Twins: Vinay Bari highlighted the concept of the "digital twin"—a virtual replica of a physical device. This technology allows for real-time data simulation to "get the optimized design, manufacturing, or the workflow related information," paving the way for predictive maintenance and improved designs.

- Prescriptive Service: The ultimate goal is to create "self-healing" medical devices that can diagnose issues and even prescribe solutions to prolong their own lifecycle.

ESG Considerations

ESG is no longer a separate activity but is becoming deeply "integrated with the product development life cycle," according to Sentil Kumar. This includes initiatives such as using biocompatible materials, reducing plastic consumption, implementing power-saving modes, and leveraging additive manufacturing. This focus on ESG in the medical device industry not only addresses environmental concerns but also aligns with the evolving values of customers and healthcare organizations.

Key Takeaways for the Future

Sustenance engineering is an indispensable function for any medical device manufacturer. It is the backbone of patient safety, regulatory compliance, and long-term business success. The discussion with industry leaders from Philips, GE Healthcare, and Reliance Industries makes it clear that the future of medical device sustenance engineering lies in a proactive, data-driven, and technology - enabled approach.

By embracing innovations like AI and digital twins and integrating ESG principles into their core strategies, organizations can not only address the challenges of today but also build a more reliable, sustainable, and effective healthcare ecosystem for tomorrow. Learning the best practices for how to maximize medical device lifespan is no longer just a competitive advantage - it's a necessity.

Author

Practice Head - Product Engineering Services

Tata Elxsi