Blog

Revisiting BLDC Motors – Combining simplicity and smartness to offer a compelling solution for Electric Vehicles

Introduction

Electric Vehicles (EVs) have transformed the global automotive landscape driven by the quest for sustainability, efficiency and reduced emissions. Electric motors are at the heart of this transformation. They are the critical component in EVs that converts electrical energy from the battery into mechanical motion, propelling the vehicle and thus the choice of traction motor directly influences an EV’s performance, efficiency and cost. The main types of electric motors currently used in EVs are brushed DC motors, Induction Motors (IM), Permanent Magnet Synchronous Motors (PMSM), Brushless DC Motor (BLDC) and Switched Reluctance Motors (SRM). The key trade-off in selecting the most suitable motor from these available options often centers on the control strategy, which plays a vital role in ensuring smooth operation and long service life. The patented technology discussed here tackles this challenge by employing a simple and cost-effective control approach that delivers smooth, torque-ripple-free performance in BLDC motors—positioning them as a highly promising choice for EV applications. The following sections provide further details.

The brushed DC motors have simple control and low initial cost but are limited by maintenance needs due to brushes and commutator wear, limited efficiency and lower lifespan. Induction motors are widely used in EVs for their robustness and lower cost due to absence of permanent magnets. But they are heavier with low torque density, less efficient at low loads, and need sophisticated control algorithms for optimal performance. Permanent magnet synchronous motors are highly efficient with excellent power density but the dependency on rare-earth permanent magnets makes them expensive. The complex control algorithms needed for the precise motor operation add to its cost. The advantages of switched reluctance motors are that they are simple in design and thus cost effective. But the high torque ripple leads to noise, vibration and harshness (NVH) challenges and complex control requirements.

Brushless DC (BLDC) motors are highly efficient with excellent torque density. BLDC are maintenance-free operation due to absence of brushes; simpler construction compared to PMSM with trapezoidal back EMF and thus enabling less complex inverter design. But the disadvantages of these BLDC are the cost implication due to permanent magnets and potential torque ripple in trapezoidal commutation. The novel technology described here addresses the torque ripple downside of BLDC by retaining the inherent simplicity and cost-effectiveness of traditional trapezoidal control.

BLDC Motor Controls

While BLDC motors offer significant merits like high efficiency across various speeds, light weight, compact design and low maintenance requirements, their performance depends heavily on the control strategy. Effective control is crucial for

- Precise torque and speed output for smooth and responsive vehicle operation

- Minimized torque ripple for improved driving comfort and reduced noise, vibration and harshness (NVH)

- Optimized power consumption for extending battery life and vehicle range

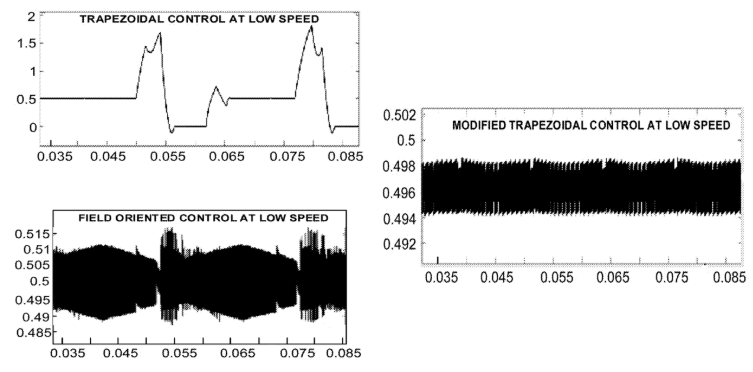

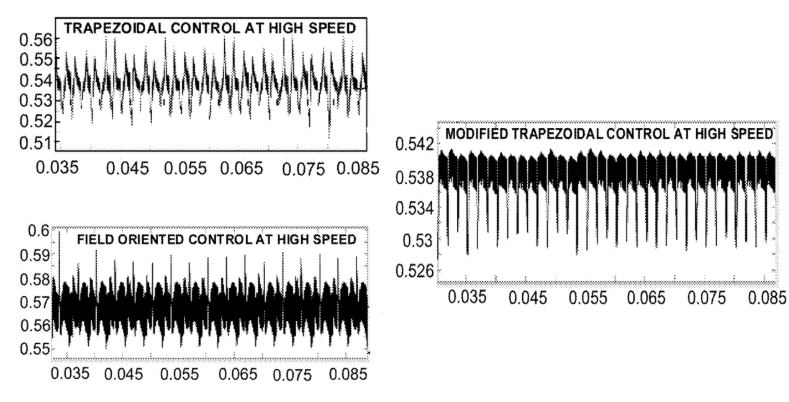

The existing control techniques for BLDC motors are namely trapezoidal control, sinusoidal control and field-oriented control (FOC). Trapezoidal control uses six-step commutation with trapezoidal shaped back-EMF. In this only two phases are energized at a time. This control technique is simple to implement and thus cost effective as only minimal controller resources are needed. But trapezoidal control introduces torque ripple generating NVH and thus affecting the efficiency of the motor.

In sinusoidal control, sinusoidal current is applied to the motor phases, requiring more complex control algorithms. However, it lacks decoupling of torque and flux. In field-oriented control (FOC), torque and flux are controlled independently by transforming 3-phase current to d-q axis (Park-Clarke transformation). This minimizes torque ripples and improves efficiency. But FOC demands high computational capability for the controller. The implementation of the controller and its tuning are complex and thus costly.

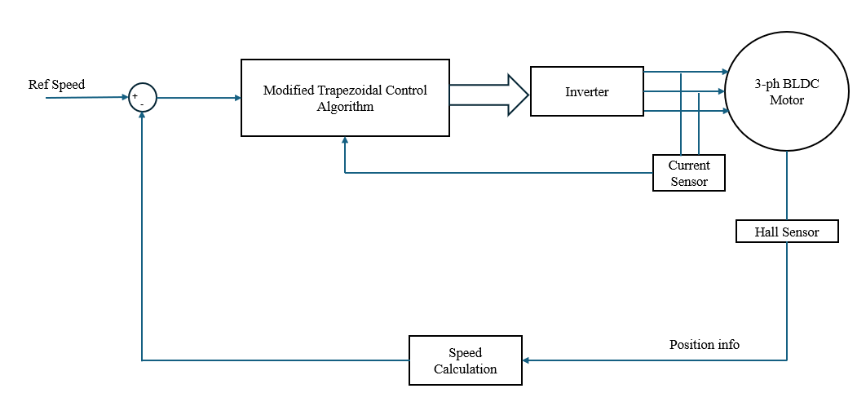

The patented modified trapezoidal control algorithm for BLDC motors addresses the torque ripples, its NVH effects and thus increases the life span of the motor. The controller includes a speed controller, current transformation module, current controller and Pulse Width Modulator (PWM) signal generator.

Fig.1 Generic block diagram of Modified Trapezoidal Control Algorithm for BLDC motors

Fig.2 Torque outputs from BLDC motor when operating at low speed

Fig.3 Torque outputs from BLDC motor when operating at high speed

Use Cases

The discussed patented technology retains the inherent simplicity and cost-effectiveness of traditional trapezoidal control while achieving efficient torque output regulation across all operational speeds. The broad applicability of this motor controller spans numerous sectors, including automotive traction, white goods, HVAC systems, robotics, aviation, industrial automation, healthcare devices, and various automotive subsystems such as windshield wipers, power windows, and door mechanisms.

This advancement presents significant business opportunities by offering a compelling balance between performance and cost effectiveness. The advantages offered by this improved motor control strategy translate into significant business opportunities across various sectors. In Electric and Hybrid Vehicles (EV/HEV) domain, the demand for efficient and reliable automotive traction systems is continuously growing. This cost-effective, high-performance control solution can enhance the driving experience by reducing vibrations and noise while potentially extending the lifespan of critical drivetrain components.

In white goods industries (Washing Machines, Fans, Pumps), noise reduction and extended product life are key differentiators. This control strategy offers a compelling advantage by improving operational smoothness and durability without significantly increasing manufacturing costs. For automotive convenience systems (Power Windows, Seats, Wipers, HVAC), the demand for quiet and reliable automotive comfort and convenience features is increasing. This control solution can enhance the perceived quality and longevity of these systems. In industrial automation and robotics vertical, smooth and precise motor control is crucial in many industrial applications. The reduced vibration and enhanced efficiency offered by this strategy can improve the performance and reliability of robotic arms, conveyor systems, and other automated machinery. For aviation and healthcare devices, reliability and smooth operation are paramount. This control strategy can contribute to enhanced performance and safety in critical applications.

The ability to offer a motor control solution that balances high performance with cost-effectiveness presents a significant competitive advantage for manufacturers across these diverse industries. This innovation enables the development of more reliable, quieter, and longer-lasting products, ultimately enhancing customer satisfaction and driving market growth.

Motor Controls Expertise of Tata Elxsi

Tata Elxsi has more than two decades of experience in Automotive electronics and mechanical system design and development. Right from the early stages of the electric and hybrid electric vehicles revolution, we were involved in developing electric motors and related solutions for global auto makers. Tata Elxsi provided its engineering services in various stages of design and development of motors, inverters, controllers and cloud applications for the monitoring and control of motors. We have expertise in various types of motor technologies such as BLDC, Induction motors, PMSM, SynRM and EESM.

The engineering services that we provide includes mechanical design, simulations, electromagnetic design, thermal system design, Inverter design, motor controller design, control algorithms design and development, software design which includes platform software and application software, safety analysis, testing and validation, testing infrastructure design, cloud based solutions, digital twin, virtual design and validation to name a few.

Conclusion

As electric vehicles continue to reshape the future of mobility, the performance and control of traction motors remain central to their success. Among the various types of traction motors available, BLDC motors stand out for their high efficiency, compactness, and low maintenance needs—making them a compelling choice for EV applications. While traditional trapezoidal control offers simplicity and cost benefits, it falls short in addressing torque ripple and NVH challenges. Conversely, FOC delivers smoother performance but at the expense of complexity and higher cost.

The patented modified trapezoidal control algorithm strikes an effective balance - minimizing torque ripples while preserving the simplicity and cost-effectiveness of the trapezoidal approach. This innovation bridges the gap between affordability and performance, reinforcing the role of BLDC motors as a practical and powerful solution in driving the EV revolution forward.

Reference

- System and Method for Controlling Operation of a Motor, US Patent Number: US 12328090