Case Study

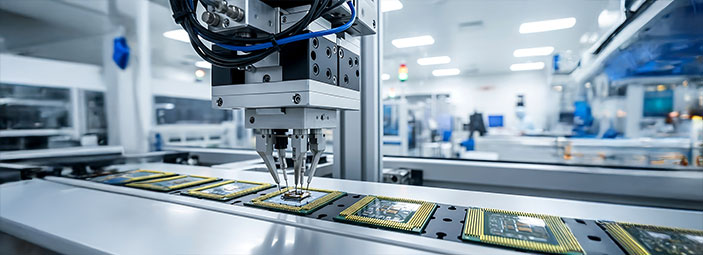

Digitizing Manufacturing Operations with Real-time Track & Trace

Connected | Traceable | Sustainable

80%

Increase in Production Efficiency

30%

Improvement in Quality Inspection

50%

Increase in Resource Tracking & Utilization

Background

The electronics manufacturing industry is evolving faster than ever—driven by the need for agility, transparency, and sustainability. A leading global electronics manufacturer operating across multiple plants and production lines faced increasing complexity in its supply chain. The company sought to enhance efficiency, reduce waste, and ensure end-to-end traceability across operations.

To achieve this, it partnered with Tata Elxsi to modernize its manufacturing ecosystem—developing a lightweight MES, PLM-ready platform that delivers real-time visibility from raw material intake to finished goods, strengthening operational transparency and supporting Tata Group’s sustainability and digital transformation vision.

Challenges

- Fragmented Processes & Limited Visibility: Production and quality workflows were disconnected, relying on paper-based tracking and siloed data. This slowed approvals, tracking, and decision-making.

- Delayed Reporting & Decision-Making: Without real-time insights, teams could not quickly identify bottlenecks or respond to quality issues, delaying corrective actions.

- High Waste & Material Inefficiencies: Lack of end-to-end traceability led to excess scrap, rework, and inefficient use of materials, increasing operational costs.

- Traceability & Compliance Gaps: Tracking material origins and quality checkpoints across multiple stations and plants was challenging, affecting audit readiness and regulatory compliance.

- Workforce Readiness: Shifting from manual processes to digital dashboards and HMIs required training and change management to ensure smooth adoption.

Solution

Tata Elxsi developed a modular, smart manufacturing platform (TETHER) that digitized the production workflow and boosted OEE by improving first-pass yield, reducing unplanned downtime, and increasing line performance.

- Operator-Centric UI Modernization: Intuitive dashboards and interfaces empowered plant staff to adopt digital workflows quickly, reducing manual effort and errors.

- Barcode-Enabled Tracking: Real-time, component-level barcode tracking ensured precise upstream–downstream traceability across materials, subcomponents, and assemblies.

- Integrated Functional Modules: Production Scheduling & Tracking, station-level Process & Resource Management, equipment utilization, operator allocation, Quality Monitoring, and Report Generation were unified into a single platform for seamless operations.

- Centralized Data Platform: Data from multiple lines and plants was consolidated into a single source of truth, enabling real-time insights and faster decision-making.

- Hybrid & Scalable Architecture: A web-based client-server design with future-ready PLM integration ensured reliable performance and minimal downtime—acting as a lightweight MES.

Impact

Tata Elxsi’s deployment of the Track & Trace solution delivered measurable and lasting impacts:

- Minimized Waste & Scrap: Streamlined workflows and real-time visibility reduced rework, defects, and unnecessary material movement—improving overall manufacturing waste efficiency.

- Improved OEE: Digital capture of production, downtime, and quality parameters enhanced availability, performance, and quality metrics—strengthening operational excellence.

- Faster Decisions: Live dashboards and consolidated data enabled supervisors and quality engineers to identify bottlenecks instantly and take timely corrective actions.

- Stronger Compliance & Traceability: Centralized tracking ensured consistent quality and audit readiness.

- Empowered Workforce: Intuitive interfaces and automated workflows reduced manual effort and boosted productivity.

Services Rendered

- Industry 4.0

- Workflow Automation

- Digital Platform & Application Development

- Edge & IoT Integration

- UI/UX & HMI Design

- Systems Integration

- Data Analytics & Real-Time Dashboards