Case Study

Smart Heat Pump Controller Platform

Intelligent | Connected | Energy-Efficient

100%

Monitoring, Control & OTA Updates

95%

Accuracy in Predictive Maintenance

75%

Reduction in Onsite Visit

Background

A leading global manufacturer of heating and cooling systems for space and water applications embarked on a journey to modernize its product portfolio with intelligent and connected solutions. With increasing demand for energy efficiency, reliability, and user experience, the company envisioned a platform capable of operating across multiple intelligent modes—delivering precise performance for diverse residential and commercial applications.

To realize this vision, the company partnered with Tata Elxsi to design, develop, and engineer an advanced Heat Pump Drive & Controller Platform. The platform was conceived as a unified ecosystem for end users, operators, and OEMs, enabling smarter energy management, real-time monitoring and control, predictive maintenance, and a superior connected experience—redefining how the heat pump product lifecycle is managed globally.

Challenges

Achieving energy efficiency and sustainability at scale revealed fundamental challenges across monitoring, control, and system lifecycle management.

- Fragmented Monitoring & Control: Traditional heat pump systems lacked centralized, real-time visibility into performance and energy consumption, limiting proactive control and maintenance.

- Energy Optimization Gaps: The absence of intelligent scheduling and tariff awareness led to higher-than-optimal energy usage and operational inefficiencies.

- Hardware Compatibility Constraints: The platform needed to support a wide range of heat pump capacities—from 2 kW to 10 kW—requiring a scalable and reliable hardware architecture.

- Limited Remote Configuration & Upgradability: Control and drive boards required on-site configuration and firmware updates, increasing maintenance effort, downtime, and lifecycle costs.

- Predictive Maintenance Readiness: There was no mechanism to anticipate failures or prevent unplanned downtime, increasing service costs and impacting reliability.

- Fragmented User Access: OEMs, operators, distributors, and end users required differentiated access and insights, which legacy systems were unable to provide.

- Global Usability Requirements: The solution had to support multilingual interfaces, intuitive user experiences, and easy configuration for global deployments.

Solution

Tata Elxsi engineered a comprehensive Heat Pump Drive & Controller Platform — a fully integrated system combining hardware, firmware, and software to deliver a connected, intelligent, and user-friendly experience for global aquatic applications.

- Unified Platform for All Stakeholders: A single, role-based platform serves OEMs, operators, distributors, and end users, providing controlled access, transparency, and lifecycle visibility with multilingual support.

- Advanced Hardware Architecture: Digital power drives embedded with sensors enable precise environmental monitoring, while the scalable power architecture supports motor capacities up to 10 kW, with built-in energy measurement delivering actionable insights across product variants.

- Built-in Intelligent Protections: Embedded control intelligence ensures safe and efficient operation through antifreeze protection, optimized defrost cycles, superheat control, and intelligent preheat logic across operating conditions.

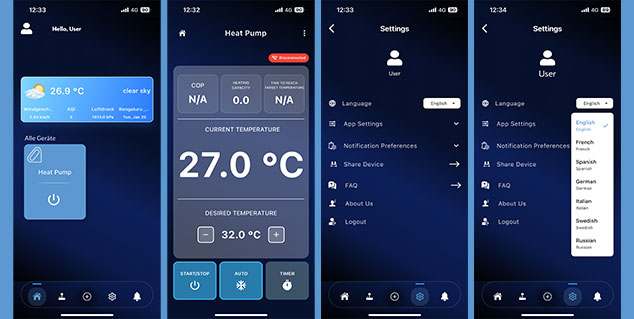

- Smart User Interfaces: Mobile applications (Android & iOS), a web portal, and an integrated on-device operator interface with Wi-Fi enable real-time monitoring, control, configuration, and diagnostics—both locally and remotely.

- Predictive Maintenance & Remote Operations: IoT connectivity, AI-driven analytics, predictive maintenance, Over-the-Air (OTA) updates, and remote debugging enable proactive fault detection, remote maintenance, and reduced downtime.

- Centralized Command & Control: A centralized command center enables continuous monitoring and lifecycle management—supporting configuration, diagnostics, performance optimization, and fleet-level oversight.

Impact

The Smart Heat Pump Controller Platform delivered measurable value across efficiency, user experience, and operational resilience.

- Energy Efficiency & Sustainability: Smart Mode intelligently schedules operations during off-peak hours, reducing energy costs and extending equipment life. Real-time energy monitoring supports sustainable operations and contributes to lower CO₂ emissions.

- Enhanced User Experience: Intuitive mobile, web, and on-device interfaces deliver real-time visibility, simplified control, and global accessibility.

- Secure and Scalable Operations: Role-based access ensures security, transparency, and collaboration across OEMs, operators, distributors, and end users.

- Future-Ready Connected Ecosystem: The cloud-enabled architecture supports continuous updates, analytics, and seamless integration across multiple pump capacities—laying the foundation for long-term product innovation.

Services Rendered

- Product Engineering

- Power Electronics and Embedded Engineering

- Digital Infrastructure

- UX/ CX Design for Mobile & Web Applications

- Pre-Certification and Product Certification Support