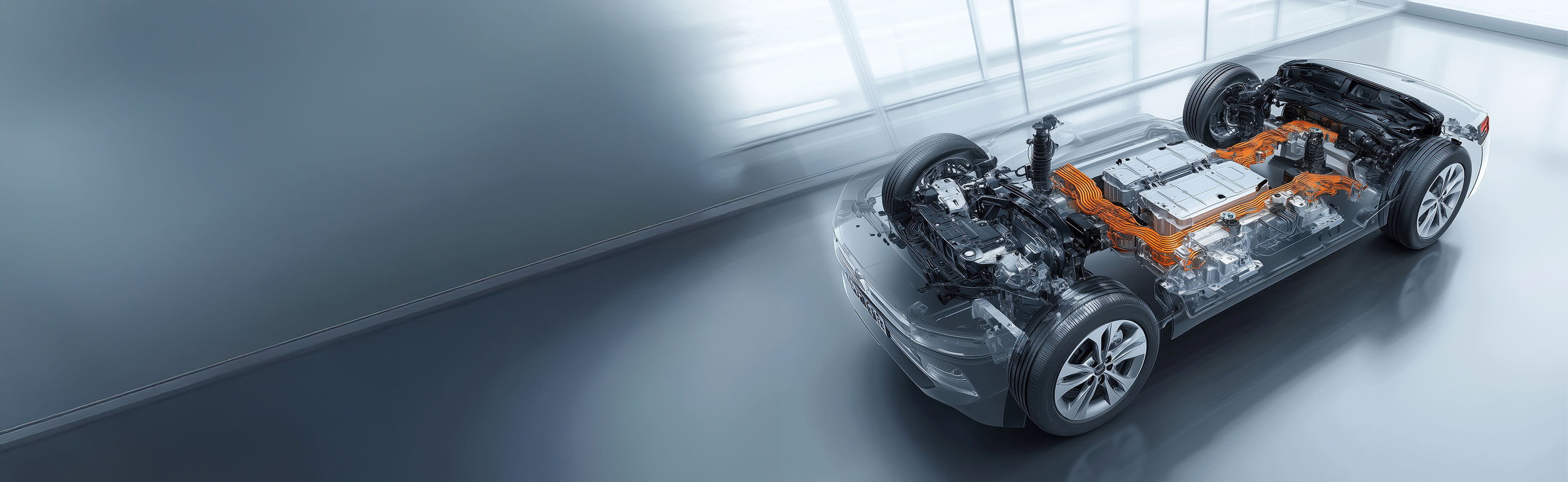

As the automotive industry pivots toward electrification, engineering teams face mounting pressure to deliver high-performance, energy-efficient electric vehicles (EVs) while navigating complex design challenges and compressed development timelines. In this dynamic landscape, 1-D virtual simulation emerges as a transformative tool—enabling smarter, faster, and more cost-effective EV development.

The Shift Toward Model-Based Engineering

Traditional EV design relies heavily on physical prototyping, which is both time-intensive and expensive. Moreover, predicting real-world performance across diverse driving conditions remains a persistent challenge. To address this, Tata Elxsi has developed a 1-D simulation framework using MATLAB/Simulink, grounded in Model-Based Systems Engineering (MBSE) principles.

This approach allows engineers to simulate and optimize subsystems—such as motors, batteries, and controllers—within a unified digital environment. The result is accelerated design iteration, early fault detection, and improved traceability from system-level requirements to component-level specifications.

Driving Efficiency Through Simulation

Our case study focused on a mid-level four-wheeler EV architecture, incorporating a Battery Electric Vehicle and WLTP drive cycles to replicate real-world conditions. The simulation framework integrates:

- PWM-based H-bridge control for motor efficiency

- Battery energy management with real-time state-of-charge tracking

- Sensitivity analysis on key parameters like mass, drag coefficient, and ambient temperature

These capabilities enable engineers to evaluate energy consumption, optimize control strategies, and refine vehicle dynamics—all before physical testing begins.

Insights That Shape Design Decisions

The sensitivity analysis revealed that vehicle mass has the most significant impact on energy consumption, followed by aerodynamic factors and battery characteristics. For instance:

- Higher internal resistance leads to non-linear energy losses

- Ambient temperature affects motor and battery efficiency

- Smaller rolling radius increases torque demand and mechanical load

Such insights empower design teams to make informed decisions early in the development cycle, reducing time-to-market and enhancing product reliability.

Enabling Scalable Innovation

Beyond technical performance, the 1-D simulation framework supports broader industry goals:

- Cost reduction through minimized prototyping

- Regulatory adaptability via rapid design iteration

- Stakeholder collaboration through integrated modeling environments

As EV platforms become more modular and software-defined, simulation-driven design will be key to managing complexity and ensuring scalability.

Looking Ahead: AI, Digital Twins and Beyond

The future of EV engineering lies in the convergence of MBSE with emerging technologies like AI, machine learning, and digital twins. These integrations will enable predictive diagnostics, real-time optimization, and intelligent energy management—redefining how vehicles are designed, tested, and operated.

Conclusion

At Tata Elxsi, we are committed to pioneering engineering solutions that drive the future of mobility. Our 1-D virtual simulation framework is more than a tool—it’s a strategic enabler for innovation, efficiency, and sustainability in EV design. This capability combined with our advanced CAE capabilities can empower OEMs to accelerate development, reduce prototyping costs, and enhance system-level performance. As the industry evolves, simulation-led development will be the cornerstone of smarter, greener transportation.

Author

Lead Design Engineer

Tata Elxsi